使用直縫直縫自動焊接專機需要注意的問題

來源:http://www.fangzh.cn/ 發布時間:2022-08-23 瀏覽次數:0

直縫自動焊接機是自動焊接機的一種,針對直線焊縫自動化焊接的一種裝備,主要應用于大型圓筒,H型鋼生產,以及一些直線型設備的焊接,這種焊接一般焊接面積大,長度長,人工焊接的話,速度慢,工作量大。以下山東焊接專機為您講解的直縫自動焊接機使用時的一些注意事項的介紹。

The straight seam automatic welding machine is a kind of automatic welding machine. It is a kind of equipment for automatic welding of straight seams. It is mainly used in the production of large cylinders, H-shaped steel and the welding of some straight-line equipment. This welding generally has a large welding area and a long length. If it is manually welded, the speed is slow and the workload is large. The following is an introduction of some precautions for the use of the straight seam automatic welding machine explained by Shandong welding machine.

直縫自動焊接專機的使用,經常會需要一些配套的設備,才能完成作業,所以要注意的是,不同的產品,需要配備不同的焊接輔助設備。

The use of the straight seam automatic welding machine often requires some supporting equipment to complete the operation. Therefore, it should be noted that different products need to be equipped with different welding auxiliary equipment.

在長度上,超過兩千毫米以上的工件,一般由于設備本身或者工件的誤差,可能會造成焊接縫偏移,因此就需要配置跟蹤系統或者擺動系統來解決這一問題。

For workpieces with a length of more than 2000 mm, the welding seam may be offset due to the error of the equipment or workpieces. Therefore, it is necessary to configure a tracking system or a swinging system to solve this problem.

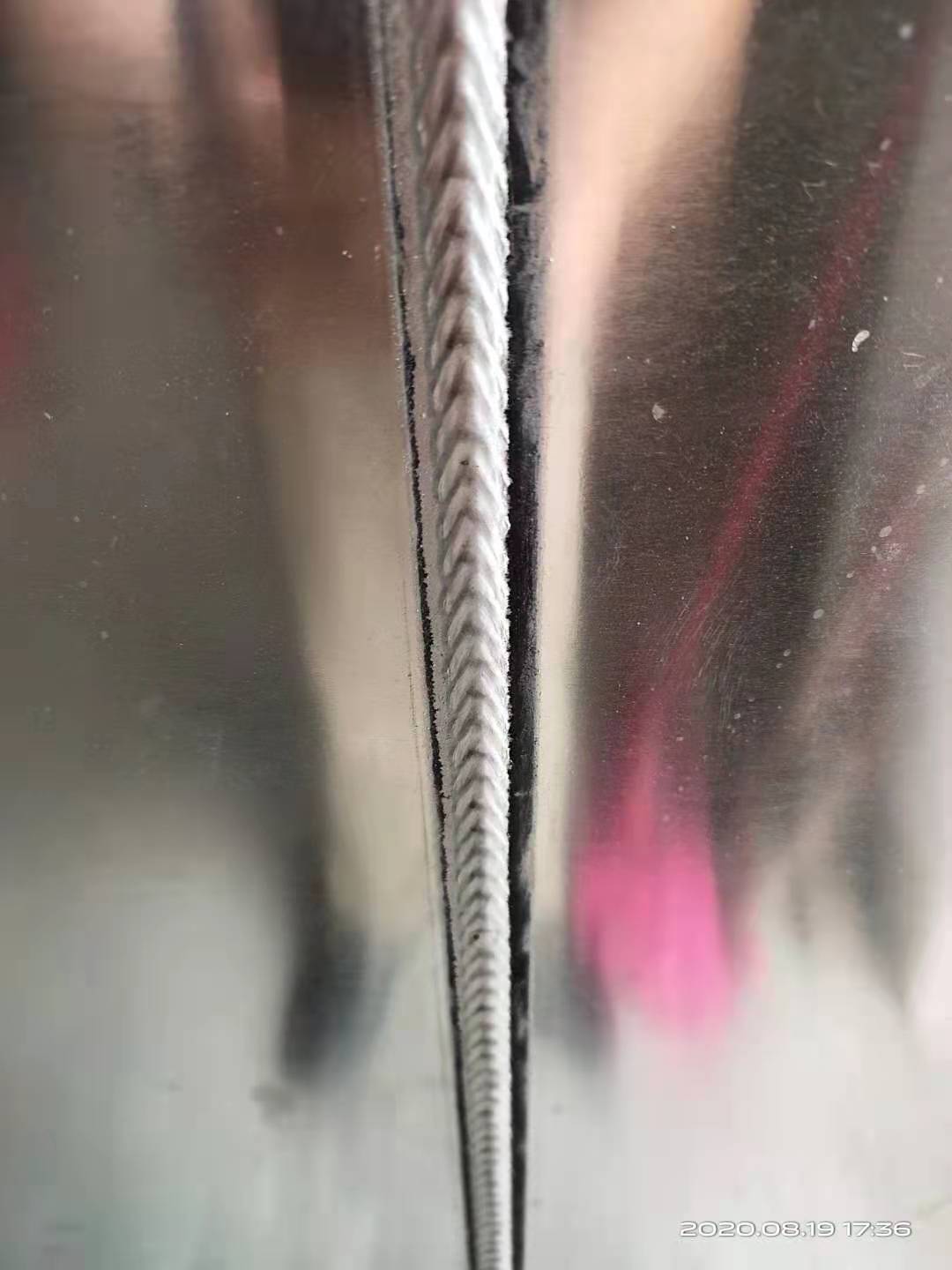

在厚度問題上,超過兩毫米以上厚度的鋼板焊接,焊縫的間隙就會比較大,采用工件的母材自身熔化不能填平焊縫,會有一定的焊接缺陷,需要加上自動填絲機構,來填平焊縫,才能完成高質量的焊接。

In terms of thickness, when the steel plate with a thickness of more than 2mm is welded, the gap between the welds will be relatively large. If the base metal of the workpiece melts itself, the weld cannot be filled, and there will be certain welding defects. It is necessary to add an automatic wire filling mechanism to fill the weld to complete high-quality welding.

直縫自動焊接專機使用時一定要注意以下問題,才能更好的使用。

When using the straight seam automatic welding machine, you must pay attention to the following problems to better use.

1、直縫自動焊接專機應放在通風干燥處,放置平穩。

1. The straight seam automatic welding machine shall be placed in a ventilated and dry place and placed stably.

2、檢查焊接面罩應無漏光、破損。焊接人員和輔助人員均應穿戴好勞保用品。

2. Check whether the welding mask is free of light leakage and damage. Welding personnel and auxiliary personnel shall wear labor protection articles.

3、交流焊機初級、次級接線應準確無誤,輸入電流應符合設備要求。嚴禁接觸初級線路帶電部分。

3. The primary and secondary wiring of AC welding machine shall be accurate, and the input current shall meet the equipment requirements. Do not touch the live part of the primary line.

4、直縫自動焊接專機焊鉗、電源線以及各接頭部位要連接可靠、絕緣良好。不允許接線處發生過熱現象,電源接線端頭不得外露,應用電膠布包好。

4. The welding tongs, power lines and joints of the straight seam automatic welding machine shall be reliably connected and well insulated. Overheating is not allowed at the wiring. The power terminal shall not be exposed. It shall be wrapped with electric adhesive cloth.

5、直縫自動焊接專機與焊鉗間導線長度不得超s過30米,特殊情況不得超過50米,導線有受潮、斷股現象應立即更換。

5. The length of the wire between the straight seam automatic welding machine and the welding tongs shall not exceed 30m, and shall not exceed 50m under special circumstances. The wire shall be replaced immediately in case of damp and broken strand.

6、次級抽頭聯結銅板必須壓緊,接線柱應有線圈。合閘前詳細檢查接點螺栓及其他元件應無松動或損壞。

6. The secondary tap connection copper plate must be pressed tightly, and the terminal should have a coil. Before closing, carefully check whether the contact bolts and other components are loose or damaged.

在設備的使用中,經常會出現一些小問題,但是如果小問題不解決的話,就有可能會造成大問題,所以說,無論是在什么樣的行業,使用什么樣的設備,大家都一定要注意細節,解決掉我們身邊存在的一些小小的問題,可能只需要幾秒鐘,幾分鐘,就能夠避免一些需要幾十分鐘,幾個小時,幾天才能解決的大問題。更多相關內容就來我們網站http://www.fangzh.cn咨詢吧。

In the use of equipment, there are often some small problems, but if the small problems are not solved, it may cause big problems. Therefore, no matter what kind of industry or equipment is used, we must pay attention to the details and solve some small problems around us. It may only take a few seconds or minutes to avoid some problems that take several minutes or hours, A big problem that can only be solved in a few days. For more information, please visit our website http://www.fangzh.cn Consult.

上一篇:淺談焊接專機的構成要素及系統組成

下一篇:火焰切割機氣路常見故障的處理