自動追頻超聲波焊接機的工作原理

來源:http://www.fangzh.cn/ 發布時間:2023-12-12 瀏覽次數:0

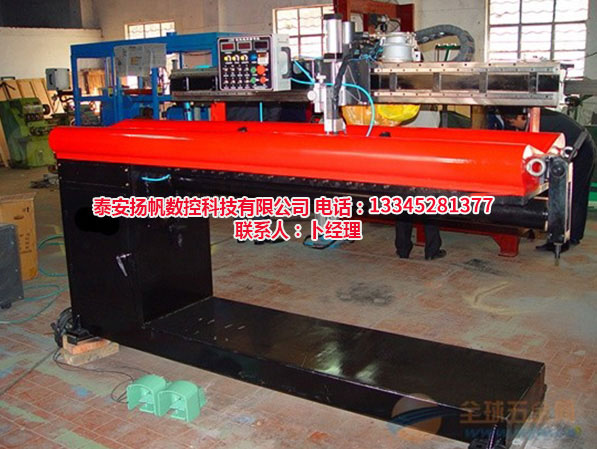

自動追頻超聲波焊接機主要由超聲波振蕩器、焊接頭部和控制系統組成。超聲波振蕩器作為核心部件,產生高頻振動;焊接頭部負責將振動傳遞到焊接材料上;控制系統則用于調節整個焊接過程的參數和參數設置。這一完整的組成結構確保了焊接的和準確性。

The automatic frequency tracking ultrasonic welding machine mainly consists of an ultrasonic oscillator, a welding head, and a control system. Ultrasonic oscillator, as the core component, generates high-frequency vibration; The welding head is responsible for transmitting vibration to the welding material; The control system is used to adjust the parameters and parameter settings of the entire welding process. This complete composition ensures the efficiency and accuracy of welding.

當焊接任務開始時,需要準備待焊接的材料。這包括清潔材料表面、去除氧化物或涂抹焊接劑等步驟,以確保焊接質量的提高。準備工作完成后,將待焊接的材料放置在焊接頭部之間,并施加適當的壓力,使材料接觸在一起。

When the welding task begins, the first step is to prepare the materials to be welded. This includes steps such as cleaning the material surface, removing oxides, or applying welding flux to ensure the improvement of welding quality. After the preparation work is completed, place the material to be welded between the welding heads and apply appropriate pressure to make the materials come into contact.

接下來是能量傳遞的過程。超聲波振動通過焊接頭部傳遞到接觸的材料上。這種振動引起材料分子之間的摩擦和振動,從而產生熱能。這個過程類似于我們在搓手時感受到的熱量。

The next step is the process of energy transfer. Ultrasonic vibration is transmitted to the material in contact through the welding head. This vibration causes friction and vibration between material molecules, thereby generating thermal energy. This process is similar to the heat we feel when rubbing our hands.

需要注意的是,熱能的控制關重要。超高溫度可能導致材料過熱或燒焦,從而影響焊接質量。因此,自動追頻超聲波焊接機的控制系統會根據焊接材料的特性和要求,自動調整超聲波振蕩器的頻率和功率,以確保熱能得到適當的傳遞。

It should be noted that the control of thermal energy is crucial. Ultra high temperatures may cause materials to overheat or burn, thereby affecting welding quality. Therefore, the control system of the automatic frequency tracking ultrasonic welding machine will automatically adjust the frequency and power of the ultrasonic oscillator according to the characteristics and requirements of the welding material, to ensure that thermal energy is appropriately transmitted.

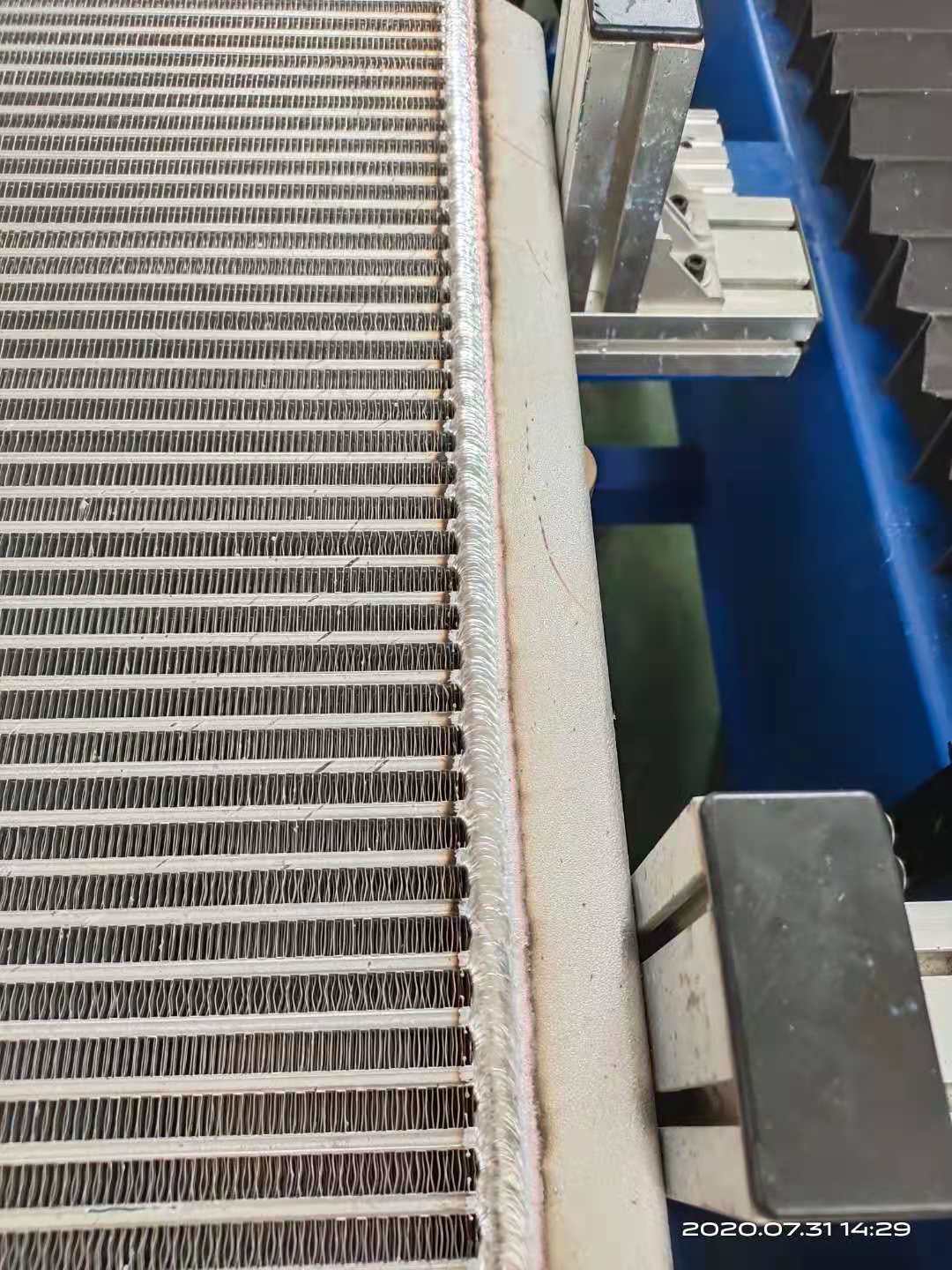

當材料達到熔點并熔融時,焊接頭部會施加額外的壓力,將熔融區域壓合在一起。這有助于形成堅固的焊縫或連接。一旦施加的壓力解除,焊接區域會逐漸冷卻和固化,形成牢固的連接。

When the material reaches its melting point and melts, the welding head will apply additional pressure to press the molten area together. This helps to form strong welds or connections. Once the applied pressure is relieved, the welding area will gradually cool and solidify, forming a strong connection.

自動追頻超聲波焊接機具有許多優勢。它的操作非常簡單,只需準備材料并設置相應的參數即可。焊接速度快,大大提高了生產效率。此外,由于焊接頭部較小,可以在狹小的空間內進行焊接。重要的是,它能夠實現高強度的焊接,確保焊接質量的可靠性

The automatic frequency tracking ultrasonic welding machine has many advantages. Its operation is very simple, just prepare the materials and set the corresponding parameters. The welding speed is fast, greatly improving production efficiency. In addition, due to the small welding head, welding can be carried out in narrow spaces. Importantly, it can achieve high-strength welding and ensure the reliability of welding quality

本文由山東自動焊接設備整理發布,您是不是對這些內容有所了解了呢?更多的內容請點擊:http://www.fangzh.cn我們會有更多精彩內容等你查看

This article is organized and published by Shandong Automatic Welding Equipment. Do you have any understanding of these contents? For more information, please click on: http://www.fangzh.cn We will have more exciting content waiting for you to view

上一篇:自動環縫焊接設備的特點介紹

下一篇:環縫焊接專機的工作原理及特點介紹