一般常見的焊接缺陷有哪些?

來源:http://www.fangzh.cn/ 發布時間:2022-06-17 瀏覽次數:0

一、 一般常見的焊接缺陷可分為四類:

1、 Common welding defects can be divided into four categories:

(1)焊縫尺寸不符合要求:如焊縫過高、過寬、過窄、高低差過大、焊縫過渡到母材不圓滑等。

(1) The weld size does not meet the requirements: for example, the weld is too high, too wide, too narrow, the height difference is too large, and the weld transition to the base metal is not smooth.

(2)焊接表面缺陷:如咬邊、焊瘤、內凹、滿溢、未焊透、表面氣孔、表面裂紋等。

(2) Welding surface defects: such as undercut, overlap, concave, overflow, incomplete penetration, surface porosity, surface crack, etc.

(3)焊縫內部缺陷:如氣孔、夾渣、裂紋、未熔合、夾鎢、雙面焊的未焊透等。

(3) Internal defects of weld: such as air hole, slag inclusion, crack, incomplete fusion, tungsten inclusion, incomplete penetration of double-sided welding, etc.

(4)焊接接頭性能不符合要求:因過熱、過燒等原因導致焊接接頭的機械性能、抗腐蝕性能降低等。 `

(4) The performance of the welded joint does not meet the requirements: the mechanical properties and corrosion resistance of the welded joint are reduced due to overheating, overburning and other reasons`

二、 焊接缺陷

2、 Welding defects

(一)焊接變形

(1) Welding deformation

工件焊后一般都會產生變形,如果變形量超過允許值,就會影響使用。

Generally, the workpiece will be deformed after welding. If the deformation exceeds the allowable value, it will affect the use.

產生的主要原因是焊件不均勻地局部加熱和冷卻。因為焊接時,焊件僅在局部區域被加熱到高溫,離焊縫愈近,溫度愈高,膨脹也愈大。

The main reason is uneven local heating and cooling of weldments. During welding, the weldment is heated to high temperature only in local areas. The closer it is to the weld, the higher the temperature and the greater the expansion.

但是,加熱區域的金屬因受到周圍溫度較低的金屬阻止,卻不能自由膨脹;而冷卻時又由于周圍金屬的牽制不能自由地收縮。

However, the metal in the heating area can not expand freely due to the metal with lower ambient temperature; When cooling, it can not shrink freely due to the restriction of surrounding metal.

結果這部分加熱的金屬存在拉應力,而其它部分的金屬則存在與之平衡的壓應力。

As a result, the metal heated in this part has tensile stress, while the metal in other parts has compressive stress in equilibrium with it.

當這些應力超過金屬的屈服極限時,將產生焊接變形;當超過金屬的強度極限時,則會出現裂縫。

When these stresses exceed the yield limit of metal, welding deformation will occur; When the strength limit of metal is exceeded, cracks will appear.

(二)焊縫的外部缺陷

(2) External defects of welds

1.焊縫增強過高

1. weld reinforcement is too high

當焊接坡口的角度開得太小或焊接電流過小時,均會出現這種現象。因此,為提高壓力容器的疲勞壽命,要求將焊縫的增強高鏟平。

This phenomenon occurs when the angle of the welding groove is too small or the welding current is too small. Therefore, in order to improve the fatigue life of pressure vessels, it is required to flatten the weld reinforcement.

2.焊縫過凹

2. the weld is too concave

因焊縫工作截面的減小而使接頭處的強度降低。

The strength of the joint is reduced due to the reduction of the working section of the weld.

3.焊縫咬邊

3. weld undercut

在工件上沿焊縫邊緣所形成的凹陷叫咬邊。它不僅減少了接頭工作截面,而且在咬邊處造成嚴重的應力集中。

The depression formed along the weld edge on the workpiece is called undercut. It not only reduces the working section of the joint, but also causes serious stress concentration at the undercut.

4.焊瘤

4. weld beading

熔化金屬流到溶池邊緣未溶化的工件上,堆積形成焊瘤,它與工件沒有熔合。焊瘤對靜載強度無影響,但會引起應力集中,使動載強度降低。

The molten metal flows to the unmelted workpiece at the edge of the molten pool and accumulates to form a weld bead, which is not fused with the workpiece. The weld bead has no effect on the static load strength, but it will cause stress concentration and reduce the dynamic load strength.

5.燒穿

5. burn through

燒穿是指部分熔化金屬從焊縫反面漏出,甚燒穿成洞,它使接頭強度下降。

Burn through refers to the leakage of some molten metal from the reverse side of the weld, or even burn through into holes, which reduces the strength of the joint.

以上五種缺陷存在于焊縫的外表,肉眼就能發現,并可及時補焊。

The above five defects exist in the appearance of the weld, which can be found by naked eyes and can be repaired in time.

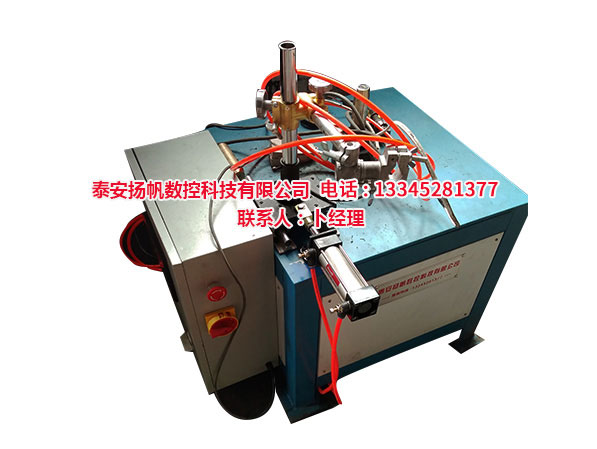

以上就是為大家介紹的山東數控焊接設備http://www.fangzh.cn有關的詳細的介紹,希望對您有所幫助.如果您有什么疑問的話,歡迎聯系我們.我們將以的態度,為您提供服務.

The above is the Shandong CNC welding equipment introduced to you http://www.fangzh.cn I hope that the detailed introduction to the will be helpful to you If you have any questions, please contact us We will provide you with professional service

上一篇:如何焊好管道焊縫

下一篇:自動焊接設備搭配焊接變位機進行協調使用