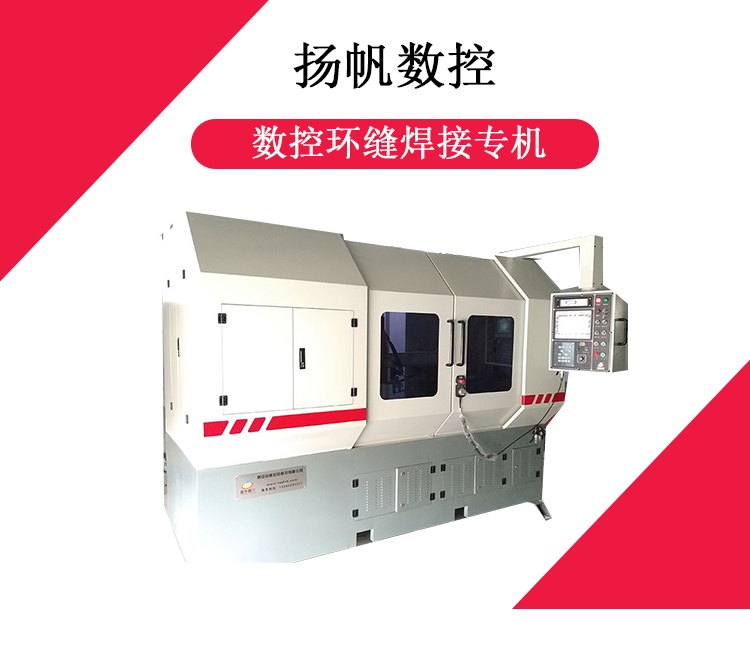

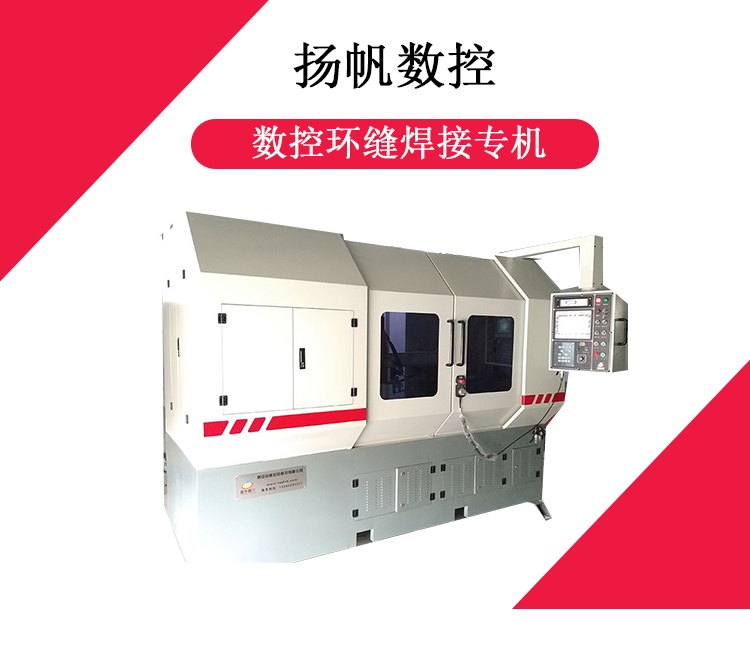

數控焊接設備深受用戶喜愛的原因

來源:http://www.fangzh.cn/ 發布時間:2023-11-04 瀏覽次數:0

一、更加節約成本

1、 More cost saving

目前勞動力成本出現了大幅的增長,雖然企業購置數控焊接設備需要花費一定的資金成本,但長期來看這種數控焊接設備無論是焊接效率還是焊接精度都遠超手動操作的模式,同時還能夠為企業節省下大量的人力成本,從這一點來看企業使用數控焊接設備品質保證的產品在成本費用上是比較劃算的。

At present, there has been a significant increase in labor costs. Although companies need to spend a certain amount of capital to purchase CNC welding equipment, in the long run, this type of CNC welding equipment far exceeds the manual operation mode in terms of welding efficiency and accuracy. At the same time, it can also save a lot of labor costs for enterprises. From this perspective, using CNC welding equipment to ensure quality of products is relatively cost-effective in terms of cost.

二、設備性能出色

2、 Excellent equipment performance

和傳統的人工手動焊接工藝相比的數控焊接設備在焊接方式和焊接效率上有很大的改善,強大的數控焊接設備中自帶微電腦控制芯片,在焊接中使用時只需要手動輸入參數數,控焊接設備即可根據指示自行進行高精度高自動化的無縫焊接操作,同時焊接時的精度相比人工焊接也有極大的提高而其焊接效率更是遠遠超過了手工操作的模式。

Compared with traditional manual welding processes, high-quality CNC welding equipment has significant improvements in welding methods and welding efficiency. The advanced and powerful CNC welding equipment comes with a microcomputer control chip, which only requires manual input of parameter numbers when used in welding. The control welding equipment can perform high-precision and automated seamless welding operations according to instructions, At the same time, the accuracy of welding is greatly improved compared to manual welding, and its welding efficiency far exceeds that of manual operation mode.

三、維護簡單方便

3、 Easy and convenient maintenance

智能化自動化的數控焊接設備雖然是一種高科技高精度的加工設備,但這種無縫焊接設備不但結構簡單同時在后期維護時的操作也非常的簡單方便,只需要對實際使用數控焊接設備的人員進行簡單的維護培訓,在平時的操作中按照產品說明書的規范要求操作即可實現數控焊接設備的后期維護。

Although intelligent and automated CNC welding equipment is a high-tech and high-precision processing equipment, this seamless welding equipment not only has a simple structure but also is very simple and convenient to operate during later maintenance. Simply provide maintenance training for personnel who actually use CNC welding equipment, and operate according to the specifications of the product manual in daily operations to achieve later maintenance of CNC welding equipment.

高精度高自主性的數控焊接設備的出現幫助企業進入了自動化生產模式,并且有效的提高了高科技設備制造企業的生產效率和產品品質。數控焊接設備這種數控加工設備的實際性能極為出色,同時也能夠為企業節省下生產成本,后期的維護操作也非常的簡單方便。

The emergence of high-precision and highly autonomous CNC welding equipment has helped enterprises enter an automated production mode, and effectively improved the production efficiency and product quality of high-tech equipment manufacturing enterprises. The actual performance of CNC welding equipment is extremely excellent, and it can also save production costs for enterprises. The maintenance operation in the later stage is also very simple and convenient.

本文由山東數控焊接設備友情奉獻.更多有關的知識請點擊 http://www.fangzh.cn真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is dedicated by Shandong CNC welding equipment. For more relevant knowledge, please click http://www.fangzh.cn Sincere attitude. We will provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Stay tuned

上一篇:自動焊接設備在工業生產中的作用

下一篇:對自動焊接設備進行性能檢測及質量控制方式