焊接機器人焊接時應該注意什么?

來源:http://www.fangzh.cn/ 發布時間:2024-11-01 瀏覽次數:0

焊接機器人在出廠前已經校準到初始位置,但仍然需要在機器人安裝時進行位置的測量和工具位置的檢查。這一步比較簡單——您只需要在焊接機器人設置中找到菜單并按照分步說明進行操作即可。

The welding robot has been calibrated to its initial position before leaving the factory, but it still needs to measure the center of gravity position and check the tool position during robot installation. This step is relatively simple - you just need to find the menu in the welding robot settings and follow the step-by-step instructions to operate.

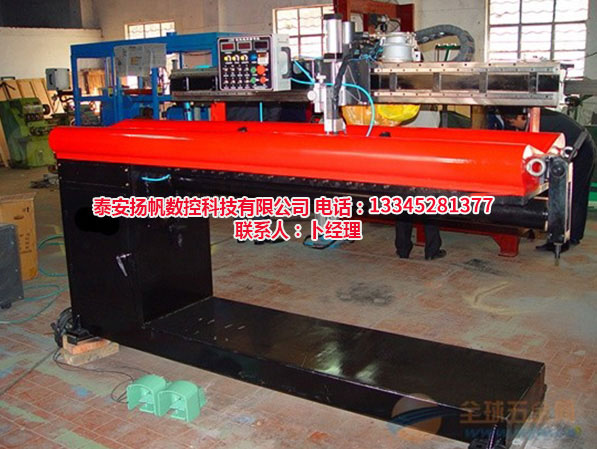

焊接機器人

Welding robot

操作焊接機器人前,請注意檢查電控箱內是否有水或油。如果電器受潮,請不要開機,檢查電源電壓是否恒定,前后門開關是否正常。檢查電機旋轉方向是否一致。然后打開電源。

Before operating the welding robot, please pay attention to checking whether there is water or oil in the electrical control box. If the electrical appliance is damp, please do not turn it on and check whether the power supply voltage is constant and whether the front and rear safety door switches are normal. Check if the rotation direction of the motor is consistent. Then turn on the power.

焊接機器人的使用可以降低廢品率和產品成本,提高機床的利用率,降低因工人故障導致零件缺陷的風險。它帶來的一系列好處也非常明顯,比如減少人工量和減少機床損耗,加速技術創新,提高企業競爭力。機器人具備執行各種任務的能力,尤其是高風險任務,平均無故障時間超過6萬小時,超過傳統自動化流程。

The use of welding robots can reduce scrap rates and product costs, improve the utilization of machine tools, and reduce the risk of parts defects caused by worker failures. The series of benefits it brings are also very obvious, such as reducing manual labor and minimizing machine tool wear and tear, accelerating technological innovation, and improving enterprise competitiveness. Robots have the ability to perform various tasks, especially high-risk tasks, with an average time between failures exceeding 60000 hours, surpassing traditional automation processes.

焊接機器人可以代替日益昂貴的勞動力,同時提高工作效率和產品質量。富士康機器人可在生產線上執行精密零件組裝任務,可替代噴涂、焊接、組裝等惡劣工作環境下的手工作業,并可與超精密鐵床CNC等機床結合使用。用于模具加工以提高生產效率和更換零件不熟練的工人。

Welding robots can replace increasingly expensive labor while improving work efficiency and product quality. Foxconn robots can perform precision part assembly tasks on production lines, replacing manual operations such as spraying, welding, and assembly in harsh working environments, and can be combined with ultra precision iron bed CNC and other machine tools. Used for mold processing to improve production efficiency and replace unskilled workers.

焊接機器人的性能不斷提高(高速、高精度、高可靠性、易操作和維護),機器人控制器系統也在向基于PC的開放式控制器發展,便于標準化、網絡化。設備集成度提高,控制柜變得更小、更精致,模塊化結構大大提高了系統的可靠性、易操作性和維護性。虛擬現實技術在機器人中的作用已經從模擬和測試發展到控制過程,遙控機器人操作員創造了在遠程工作環境中操縱機器人的感覺。

The performance of welding robots is constantly improving (high speed, high precision, high reliability, easy operation and maintenance), and the robot controller system is also developing towards PC based open controllers for standardization and networking. The integration of equipment has improved, and the control cabinet has become smaller and more refined. The modular structure greatly enhances the reliability, ease of operation, and maintainability of the system. The role of virtual reality technology in robots has evolved from simulation and testing to control processes, with remote-controlled robot operators creating the feeling of manipulating robots in remote work environments.

焊接機器人

Welding robot

當需要拆卸焊接機器人時,關閉注射機電源,機械手電源關閉,機械手氣壓源關閉。放氣壓力。松開拉缸固定板上的固定螺釘,將臂移近弓。將保險杠座椅靠近扶手。擰緊拉缸固定板,使臂不能移動。鎖定旋轉的螺釘,使機械手無法旋轉等,這些細節要注意。

When disassembling the welding robot, turn off the power supply of the injection machine, the power supply of the robotic arm, and the pneumatic source of the robotic arm. Release pressure. Loosen the fixing screws on the cylinder fixing plate and move the arm closer to the bow. Place the bumper seat close to the armrest. Tighten the cylinder fixing plate to prevent the arm from moving. Pay attention to details such as locking the rotating safety screw to prevent the robotic arm from rotating.

本文來自:山東數控焊接設備更多精彩內容請點擊我們的網站:http://www.fangzh.cn我們將傾情為您解答。

This article is from Shandong CNC Welding Equipment. For more exciting content, please click on our website: http://www.fangzh.cn We will wholeheartedly provide you with answers.

上一篇:在選擇和使用焊接設備時需要考慮的因素

下一篇:使用焊接設備該怎么選