焊接機器人運行時熔池的溫度及因素

來源:http://www.fangzh.cn/ 發布時間:2021-12-07 瀏覽次數:0

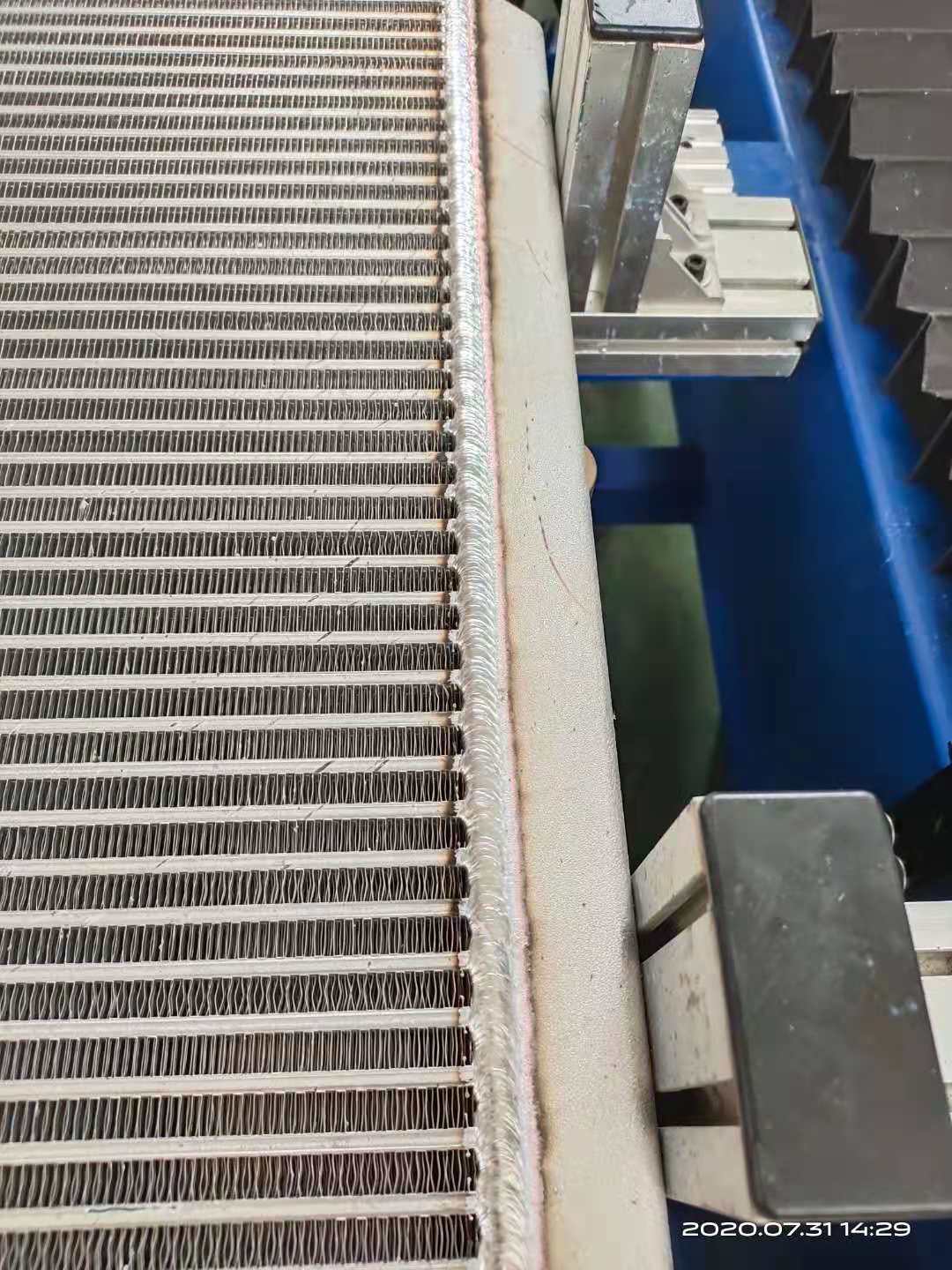

在焊接機器人焊接過程中,當電極與焊接方向的夾角為90度時,電弧集中,熔池溫度高;角度小,電弧分散,熔池溫度較低。例如,做12mm平焊縫封底層時,焊條的角度應控制在50-70度,以降低熔池溫度,避免背面焊接磕碰或浪涌。

In the welding process of welding robot, when the included angle between electrode and welding direction is 90 degrees, the arc is concentrated and the molten pool temperature is high; Small angle, dispersed arc and low bath temperature. For example, when making 12mm flat weld back sealing layer, the angle of welding rod shall be controlled at 50-70 degrees to reduce the temperature of molten pool and avoid back welding bump or surge.

其次,要嚴格控制焊接機器人系統的引弧時間。斷弧頻率和燃弧時間直接影響熔池溫度。由于管壁薄,承受電弧熱的能力有限。如果放慢斷弧頻率,降低熔池溫度,容易產生縮孔,所以只能利用電弧燃燒時間來控制熔池溫度,避免很高的內部焊縫或形成焊道在管道中。

Secondly, the arc striking time of welding robot system should be strictly controlled. The arc breaking frequency and arc burning time directly affect the bath temperature. Due to the thin pipe wall, the ability to withstand arc heat is limited. If the arc breaking frequency is slowed down and the weld pool temperature is reduced, it is easy to produce shrinkage. Therefore, the arc combustion time can only be used to control the weld pool temperature to avoid high internal welds or weld beads in the pipeline.

一般情況下,焊接機器人應根據焊接間隙的位置和焊接水平選擇焊接電流和焊條直徑。焊接時選擇的焊接電流和電極直徑較大,垂直和水平位置較小。只有這樣,才能更容易地控制熔池的溫度,使焊縫形成。

Generally, the welding robot should select the welding current and electrode diameter according to the position of welding gap and welding level. When welding, the welding current and electrode diameter are larger, and the vertical and horizontal positions are smaller. Only in this way can the temperature of the molten pool be controlled more easily to form the weld.

焊接機器人采用內置焊鉗,焊接變壓器安裝在焊鉗后面,所以變壓器要盡量小。對于容量較小的變壓器,可以采用50Hz供電頻率的交流電,而對于容量較大的變壓器,已經采用逆變技術將交流電從50Hz的供電頻率變為交流600-700Hz,從而減小了變壓器的體積。電壓一經變換,可直接用600-700Hz交流電焊接,也可二次整流后用直流電焊接。焊接參數使用定時器設置,見圖1b。新的計時器已經過微計算,因此機器人控制柜可以直接控制計時器,無需額外的接口。點焊機器人的焊鉗通常使用氣動焊鉗,氣動焊鉗的兩個電極之間的間隙一般只有兩級。另外,電極壓力一旦建立,就不能隨意改變。近年來出現了一種新型的伺服電動點焊槍。焊槍開合由伺服電機驅動,編碼器反饋,可根據實際需要任意選擇和預設焊槍開度。

The welding robot adopts a built-in welding clamp, and the welding transformer is installed behind the welding clamp, so the transformer should be as small as possible. For transformers with small capacity, AC power supply frequency of 50Hz can be used, while for transformers with large capacity, inverter technology has been used to change AC power supply frequency from 50Hz to AC 600-700hz, thus reducing the volume of the transformer. Once the voltage is changed, it can be directly welded with 600-700hz AC or DC after secondary rectification. The welding parameters are set by timer, as shown in Figure 1b. The new timer has been micro calculated, so the robot control cabinet can directly control the timer without additional interface. The welding tongs of spot welding robot usually use pneumatic welding tongs, and the gap between the two electrodes of pneumatic welding tongs is generally only two levels. In addition, once the electrode pressure is established, it cannot be changed at will. In recent years, a new type of servo electric spot welding gun has emerged. The opening and closing of the welding gun is driven by the servo motor and fed back by the encoder. The opening of the welding gun can be arbitrarily selected and preset according to the actual needs.

焊接機器人

welding robot

根據以往的經驗,焊接機器人使用圓形帶鋼時熔池溫度高于月牙形帶鋼的溫度,而月牙形帶鋼的溫度高于鋸齒形帶鋼的溫度跳閘。隨著凹槽兩側的振蕩和停頓幅度,熔池溫度得到有效控制。

According to previous experience, when the welding robot uses circular strip steel, the molten pool temperature is higher than that of crescent strip steel, and the temperature of crescent strip steel is higher than that of sawtooth strip steel. With the oscillation and pause amplitude on both sides of the groove, the molten pool temperature can be effectively controlled.

以上的精彩內容就是小編今天為您提供的內容,更多的精彩內容來自:山東數控焊接設備詳情請點擊我們的網站關注:http://www.fangzh.cn

The above wonderful content is what Xiaobian provides for you today. More wonderful content comes from: Shandong CNC welding equipment. For details, please click our website to pay attention to: http://www.fangzh.cn

上一篇:自動焊接設備給工程制造帶來了哪些優勢

下一篇:山東數控焊接設備各方面內容